If you’re juggling several depot locations, you already know the pain: scattered Excel files, endless phone calls, and reports that are outdated by the time they reach your desk.

What if you could see everything happening across your sites — from Marseille to Rotterdam — on a single, real-time depot visibility dashboard?

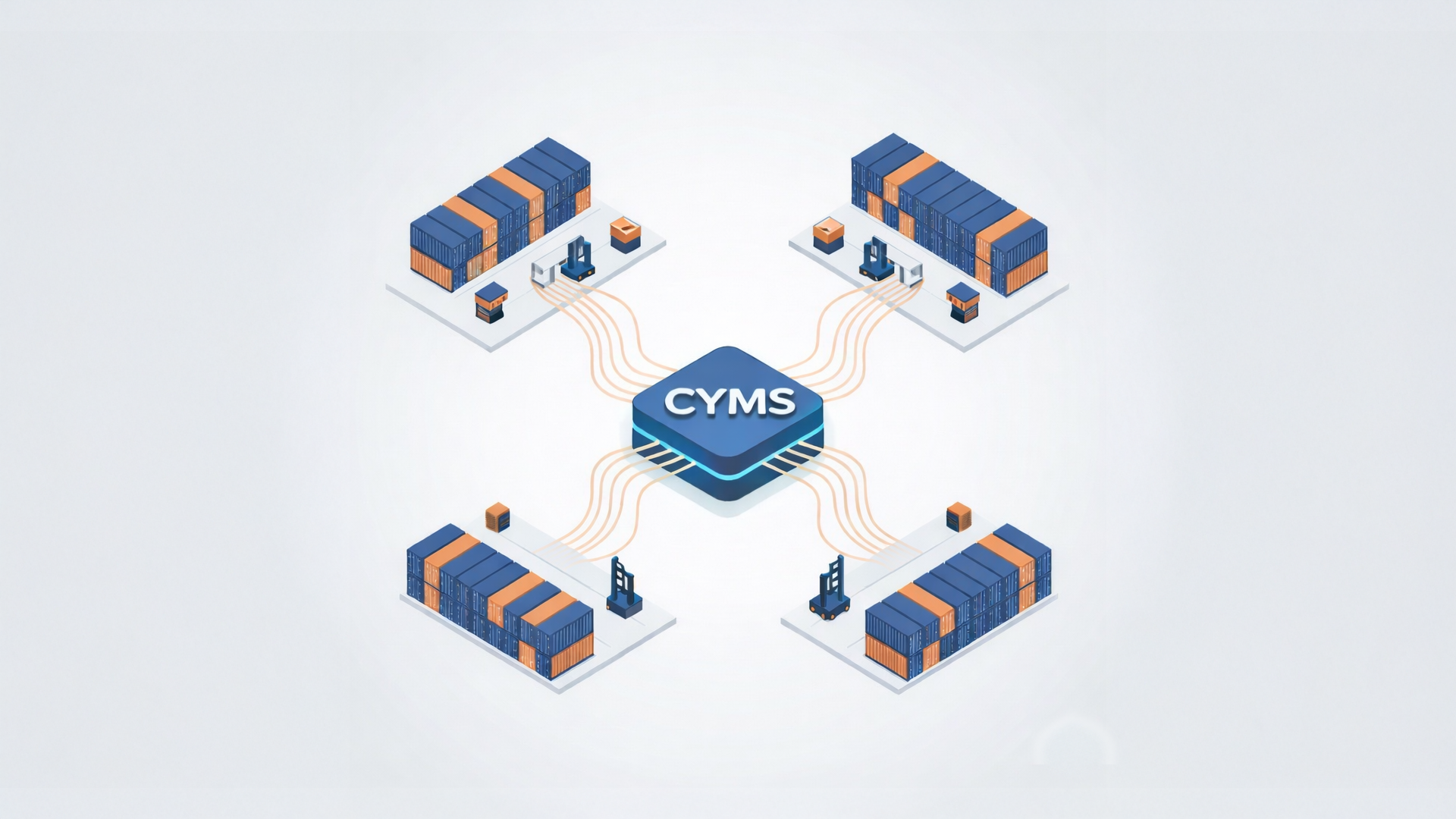

That’s exactly what Shipzzer’s container yard management system (CYMS) delivers — a centralized, intuitive solution built for digital depot operations.

Why Real-Time Visibility Changes Everything

When depots operate in silos, information becomes fragmented, slow, or incomplete. This leads to issues such as:

- A container arrives at your depot, but you have no trace of the emergency repair it underwent at the previous terminal — forcing your team to start investigations from scratch.

- Clients request availability across your network, but stock data is split between locations, making it impossible to answer instantly or optimize bookings.

- Your central spare-parts inventory serves multiple depots, yet you have no unified view of consumption trends or stock levels.

- Import/export operations involve several sites, but coordinating them requires manual updates, calls, and spreadsheet consolidation.

- Management requests performance metrics by location, and you spend hours compiling figures from disconnected systems.

All of this slows you down. Meanwhile, digital-first depots using a smart container yard management system (CYMS) respond in minutes, not hours.

Shipzzer’s platform unifies gate movements, inventory, and bookings into one live dashboard. It’s not just convenience — it’s a shift toward a connected, optimized way of working.

The Hidden Costs of Disconnected Depots

Lost Revenue Opportunities

Without a global view via container yard management system (CYMS), you may decline a booking that another site could handle, or accept one without the required equipment, resulting in costly repositioning and frustrated customers.

Wasted Staff Time

When teams must search through emails, call other departments, or navigate multiple systems just to retrieve basic info, they lose time that should be spent serving customers and optimizing operations.

Increased Container Downtime

Without real-time depot visibility, containers sit idle in one depot while another faces shortages. Every idle hour impacts profitability.

Compliance Risks

Meeting EDI standards becomes difficult when data is inconsistent or manually updated. Errors lead to rejected messages and strained partner relationships.

Decision-Making Delays

Leaders operate reactively with outdated info. Strategic planning suffers, and opportunities are missed.

- Preparing your annual budget means navigating by guesswork, while a CYMS (Container Yard Management System) with EMR and parts modules could tell you exactly what to order.

- Sizing your workforce, especially for shift ops, becomes a challenge without visibility into actual demand patterns across locations.

- Planning yard capacity – bays, reefer plugs, client allocations – requires accurate data. Without it, you waste time on container shuffling and inefficient movements.

How It Works

Step 1: Setup and Integration

Connect your depots to Shipzzer. Our team tailors the container yard management system (CYMS) to your structure, whether you have 2 or 20 locations. Setup takes days, not weeks.

We integrate with your existing hardware: tablets used in the yard for scanning and photos — no need to start from scratch.

We configure depot-client pricing, create user accounts, set up EDI flows, and tailor the system to your specific depot constraints.

Step 2: Team Onboarding

We train staff on both the web and tablet interface, define their roles, and walk through your operational processes.

Most users are confident after one shift. They’ll also learn to use the customer portal if they need to open support tickets.

Step 3: Real-Time Operations

Once your team scans containers or logs updates, data flows instantly to your central dashboard.

- No manual entry

- No spreadsheet uploads

- All workflows are automated based on role.

- All EDI messages are generated in real time.

What You Get Access To

Live Inventory Dashboard

View stock, bookings, and status (available, under repair, in transit) across all sites. Filter by depot, container type, condition, or customer.

EDI-Compliant Quote Management

Generate quotes instantly using real stock and pricing. Compliant with shipping line standards.

Repair Documentation (EMR)

Track every repair with photos, CEDEX codes, parts, and hours. Access full container repair history instantly.

Gate Operation Records

Track who approved each movement, when it happened, and in what condition. Flag issues fast.

Analytics and Reporting

Track KPIs like depot performance, turnaround times, container cycles, and revenue per depot.

Real Benefits of Going Digital

Instant Clarity

No more calls. You check stock and status across all depots from one place.

Faster Response

When a container is damaged or stock dips, teams are notified immediately.

Full Control

Every action is traceable. No more back-and-forth on accountability.

Operational Efficiency

Less time chasing data, more time optimizing ops.

Scalable Simplicity

Whether you manage 2 or 10 depots — 10,000 or 300,000 containers — Shipzzer’s multi-depot management software scales with you.

Final Thought

Managing multiple depots doesn’t have to be complicated.

With Shipzzer’s container yard management system (CYMS), your operations become streamlined, visible, and scalable.

👉Book a demo and discover how Shipzzer helps you manage your depot network with clarity, speed, and confidence.

Leave a Reply